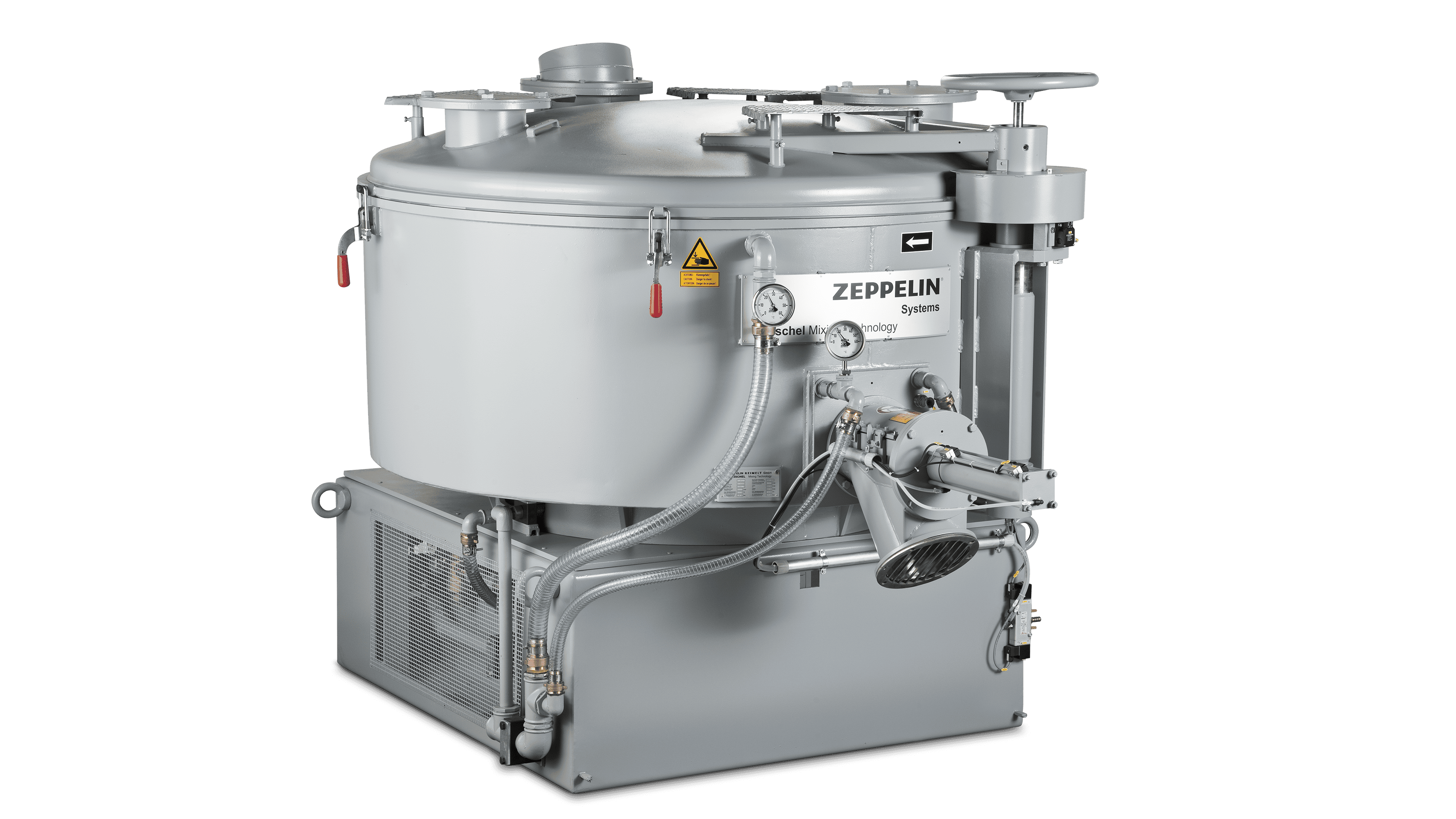

Vertical Cooling Mixer KM

Efficient cooling, clever mixing

Versatile. Powerful. Compact.

The vertical cooling mixer KM from Zeppelin Systems is the ideal solution for demanding mixing processes. With its compact design, high performance, and excellent ease of cleaning, it impresses in a wide variety of applications.

In combination with a high-intensity mixer, the KM demonstrates its strengths in applications such as bonding, compounding, masterbatch, PVC dry blend, battery compounds, engineering plastics, WPC, and many other areas of use.

Rely on proven technology – for maximum efficiency and flexibility in your production.

Key advantages at a glance:

- Short cooling times

- Compact design – ideal for smaller mixing plants

- Excellent accessibility to the mixing chamber for applications requiring frequent cleaning (e.g., bonding and masterbatch applications)

- Excellent mixing quality

- Gentle material handling

- Low dead space design

- Excellent residual emptying

- Intelligent design for minimal maintenance costs

- Control concept for intuitive operation

- Configurable for a wide range of applications in the fields of plastics, chemicals, minerals, and dyes

- Expandable with extensive options such as chopper, liquid addition, etc.

Application areas

Plastics industry

In plastics processing, cooling mixers are used after hot mixing to bring the heated material to processing temperature quickly and in a controlled manner. This prevents thermal damage and optimally prepares the mixed material for further processing.

Chemical industry

In the chemical industry, cooling mixers control exothermic reactions and gently cool sensitive substances after mixing. This not only improves product stability, but also significantly increases process safety.

Product details

Good accessibility

The fully hinged lid allows optimal accessibility for cleaning and maintenance purposes.

Intuitive mixer control

The mixer control system features an intuitive user interface that makes it easy to operate in both manual and automated modes.

Accessories and options

Perfect additions for cooling mixer KM

We offer various accessories and options for seamless integration and flexible use of our cooling mixer. These include, among others:

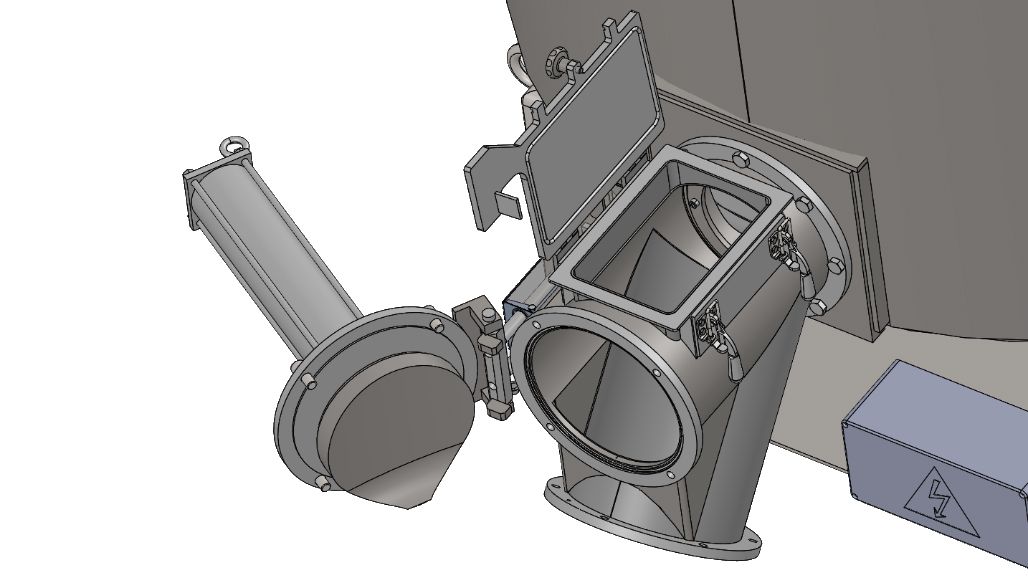

Discharge with cleaning package

The swiveling discharge cylinder enables convenient and safe handling when emptying the mixer. In addition, the inspection flap on the discharge housing ensures easy maintenance and quick inspection of the process areas—ideal for efficient processes and easy cleaning.

2/3 hinged lid

The 2/3 hinged lid allows convenient access to the mixing container and easy removal of the mixing tools—without the need to remove lid attachments such as filters, funnels, or the connection to the high-intensity mixer.

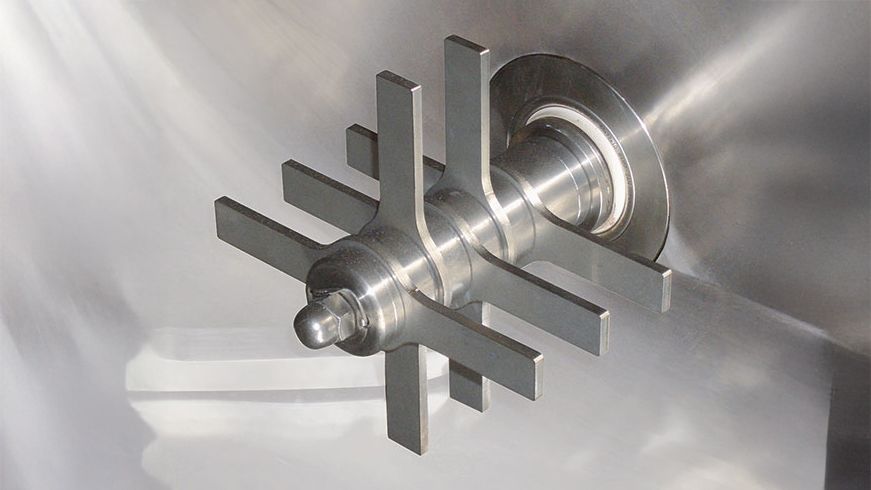

Chopper

The chopper mounted in the container wall acts as an agglomerate crusher for increased dispersion performance.

Need more details? Our contact person will be happy to assist you

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH