Laboratory Mixers

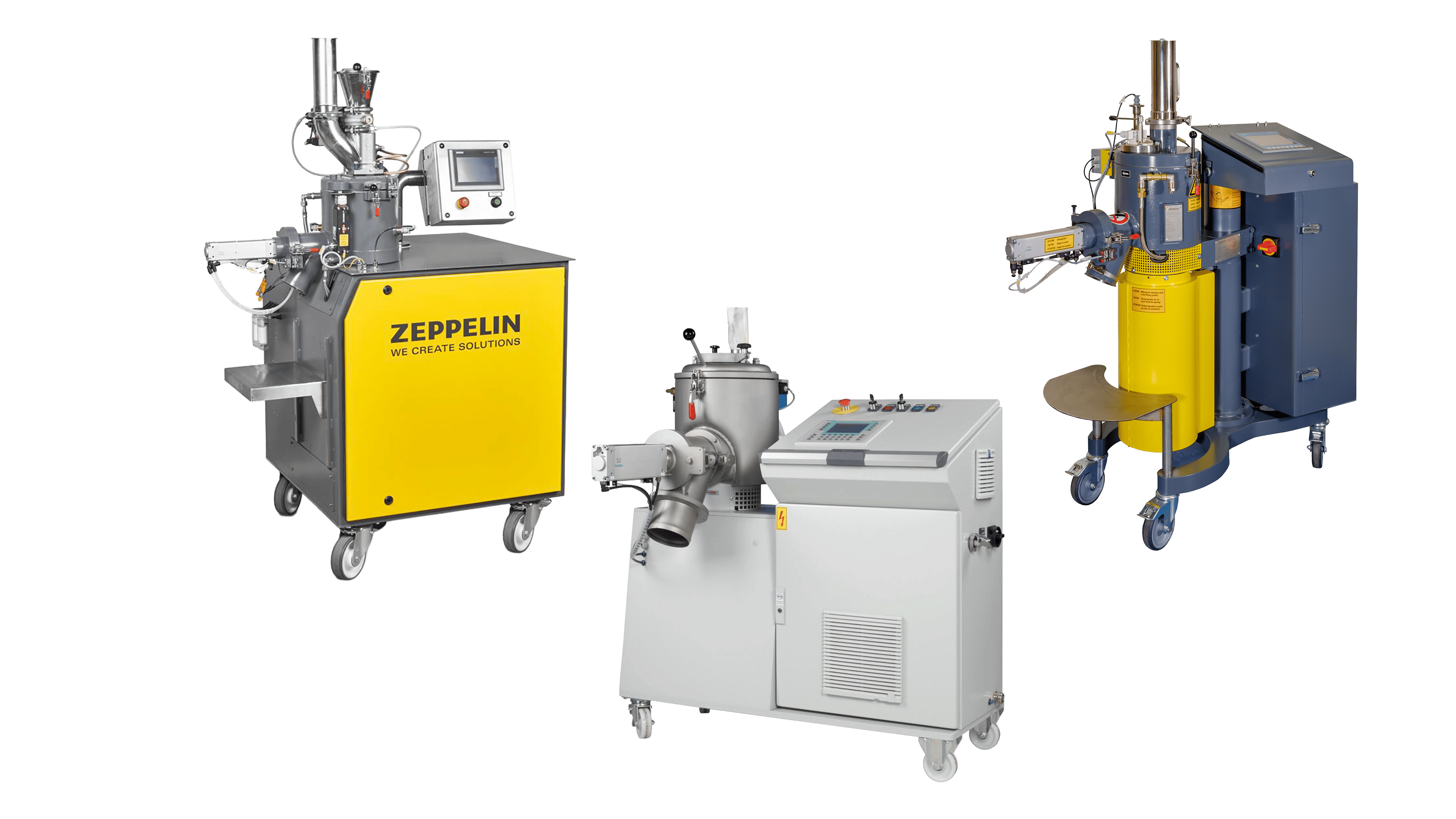

The compact versions of our production machines

The right laboratory mixers for your application

Our laboratory mixers are the ideal solution for innovative developments, trial mixtures in laboratories and technical centres, and small-scale production. Processes such as mixing, coating, compounding, bonding and granulating bulk materials can be carried out reliably on a laboratory scale. This creates a secure basis for subsequent upscaling into production.

With the laboratory mixers FML/FM, MB and M, Zeppelin Systems is consistently following the path of production plants. This means perfect design for perfect products.

Benefit from standard laboratory mixers available at short notice or individually developed solutions that are precisely tailored to your application. Features such as integrated control, quick cleaning and hinged lids are standard with us.

Key advantages at a glance

- Different sizes: 10–35 l gross volume for batches from 1.5 to 20 kg

- Compact design: All laboratory mixers have mobile stands with integrated control system (except in the ATEX area)

- Plug & play: Preconfigured in-house – simply plug in, connect compressed air (N₂) and process water if required, and you're ready to go

- Intuitive control: User-friendly operation in manual and automatic mode

- Safety: CE-certified, optional ATEX version (Standard for MB Laboratory)

The laboratory mixer types from Zeppelin Systems

Laboratory Mixer FML

The standard laboratory mixer FML 10 impresses with its wide range of applications. The process engineering features and mixer control correspond to those of production machines, allowing all processes to be simulated and tested under realistic conditions. Thanks to its compact design, the FML 10 requires little space, making it ideal for use in laboratories and technical centres.

FM Laboratory

The individually configurable Laboratory Mixer FM 10 can meet a wide range of requirements.

The process engineering features and mixer control correspond to those of production machines. This means that all processes can be mapped and tested as they would be on a production machine.

Different gear ratios and motor outputs, a coated mixing container, various ATEX versions, inerting, and residual oxygen measurement are no problem for this laboratory mixer.

M Laboratory

The Laboratory Mixer M offers a wide range of applications combined with a compact design that requires little space. The process engineering features and mixer control correspond to those of production machines. This means that all processes can be mapped and tested as on a production machine.

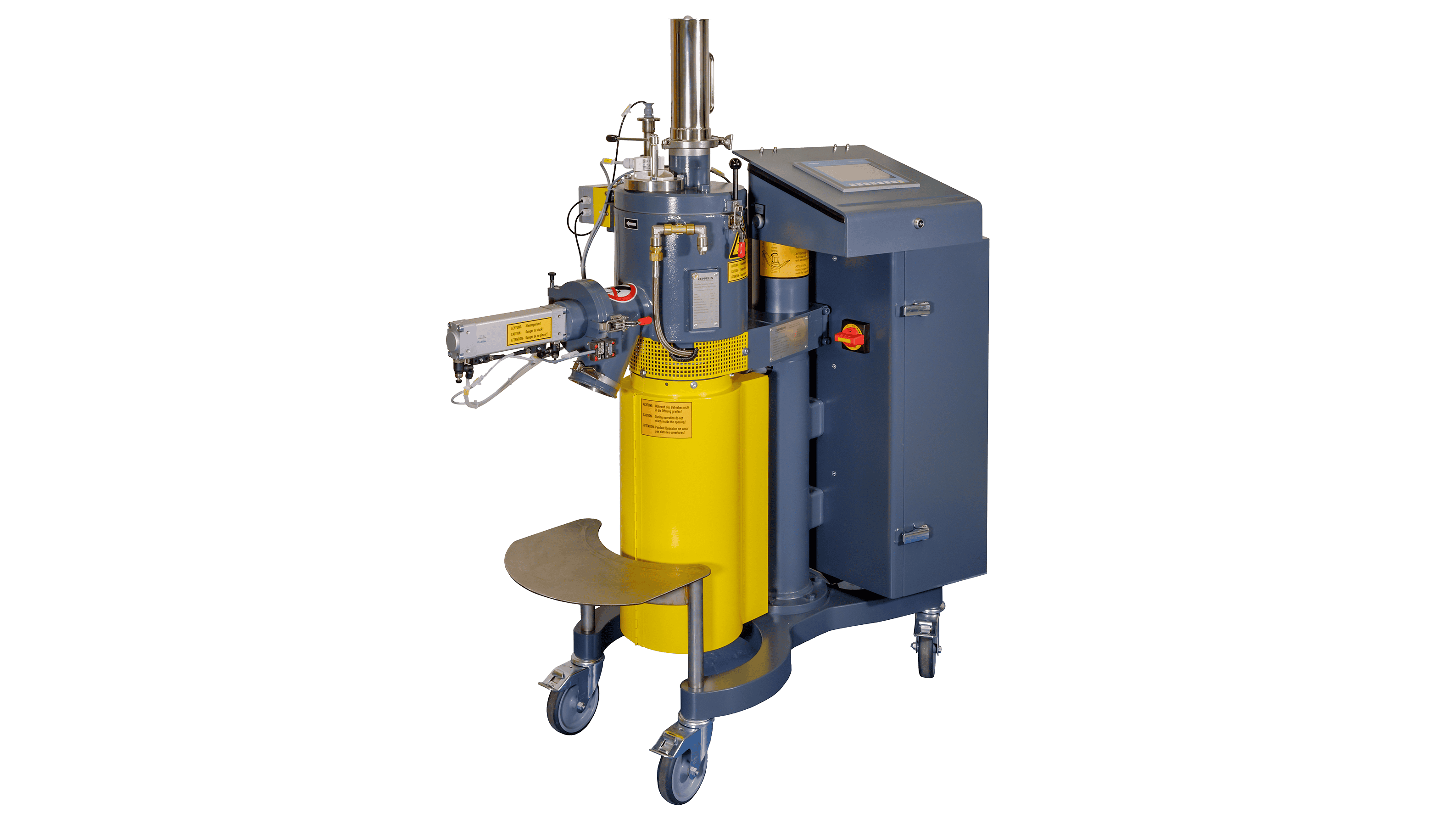

MB Laboratory

The MB 10 laboratory mixer is specially designed for bonding powder coatings. It offers the same functions as the production machines in the MB series for the best possible product quality when bonding powder coatings:

- No segregation thanks to complete bonding

- Cooled mixing tool and mixing container

- Fully automatic Tg detection

The MB 10 thus offers ideal conditions for the new and further development of different formulations and enables easy upscaling to production.

Application areas

PVC

Whether window profiles, pipes, films, or floor coverings – our mixing solutions for rigid and flexible PVC ensure consistent product quality and maximum efficiency. With innovative technologies and decades of experience, we guarantee reliable processes, optimal recipe management, and first-class results – even for complex requirements.

- Consistent quality and minimal scrap rates thanks to reproducible properties and innovative dehumidification technology.

- High performance in a compact design: throughput of up to 15 t/h, long service life, and ATEX-compliant operation.

- Perfect processing of demanding formulations for rigid and flexible PVC, including solutions for a wide variety of plasticizers.

Bonding of powder coatings

We have set new standards in the industry with our perfected bonding process for the production of metallic powder coatings. Our mixers with intelligent control technology offer the ideal solution for the special processes and requirements of these temperature-sensitive products. This allows you to produce brilliant, non-segregating, color-consistent coatings that give you a competitive edge in the international market.

- Intelligent process technology for maximum recipe diversity

- Batch tracking for precise product control

- Special explosion protection for maximum safety

- 100% control of the bonding process through process technology and automation

- Automatic Tg detection

Battery mass

High intensity mixers from Zeppelin Systems are ideal for the safe and uniform production of battery compounds using dry and semi-dry processes. High speeds and the special design of the mixing tool and container ensure that the raw materials are mixed and distributed particularly efficiently. Even very fine additives can be dispersed well, binders activated, and the particle structure specifically modified. This increases the bulk density and energy density.

- Production of battery compounds using dry or semi-dry processes

- Individual shear rates, precisely controllable temperature profiles

- Customized wear protection for long service life

- Pre-mixing for fine distribution of additives/conductive additives

Masterbatches

Masterbatches are essential in plastics processing. Our high-performance mixing systems ensure perfect dispersion and homogenization – dust-free, safe, and efficient. Benefit from over 50 years of experience in industrial mixing technology and achieve consistently optimal results.

- Very high pigment dispersion for brilliant colors

- Fast and effective homogenization for uniform mixtures

- Processing of color masterbatch, mono masterbatch, and SPC (Single Pigment Concentrates)

- Production of pigment preparations and dust-free compounds

- Easy cleaning for quick product changes

- Safe operation in compliance with ATEX guidelines for maximum process safety

Need more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Resources

Brochures for Download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH