Mixing and Kneading

Mixing, Kneading, Coating, Bonding, Compounding – you name it, we do it!

In product manufacturing, different mixing tasks need to be addressed. Since 1956, Zeppelin Systems has set standards in mixing technology with its HENSCHEL and MTI brand mixers. Whether in the plastics, chemicals, paints and coatings, or food industries, we offer the perfect solution for your mixing task, including process, handling, and processing expertise.

The product portfolio of Zeppelin Systems includes intensive mixers, cooling mixers, as well as heating/cooling mixer combinations, universal mixers, and container mixers – all customized for your specific process. Additionally, we offer various mixing and homogenizing silos, as well as pre-mixers for different doughs and the continuous dough kneading system CODOS NT.

Container Mixer CMQ

Our innovative container mixer CMQ not only works more efficiently but also ensures extremely high-quality mixing results without deviations. Whether for the production of powder coatings, masterbatches, color concentrates, or compounds – with the CMQ, you optimize your mixing process.

Go to Container Mixer CMQ

Cooling Mixer K

Fast and controlled cooling of bulk materials with our cooling mixer K. The mixer is specially designed for the requirements of the plastics and chemical industries and achieves a particularly high cooling capacity thanks to individually adjustable cooling zones and a turbulent water flow with optimum heat transfer.

Go to Cooling Mixer K

High-Intensity Mixer M

The high-intensity mixer M is flexible – whether dry, moist or with the addition of liquid. Its vertical design and the rotating mixing tools with variable peripheral speed ensure intensive, three-dimensional mixing – even with complex recipes.

Go to High-Intensity Mixer M

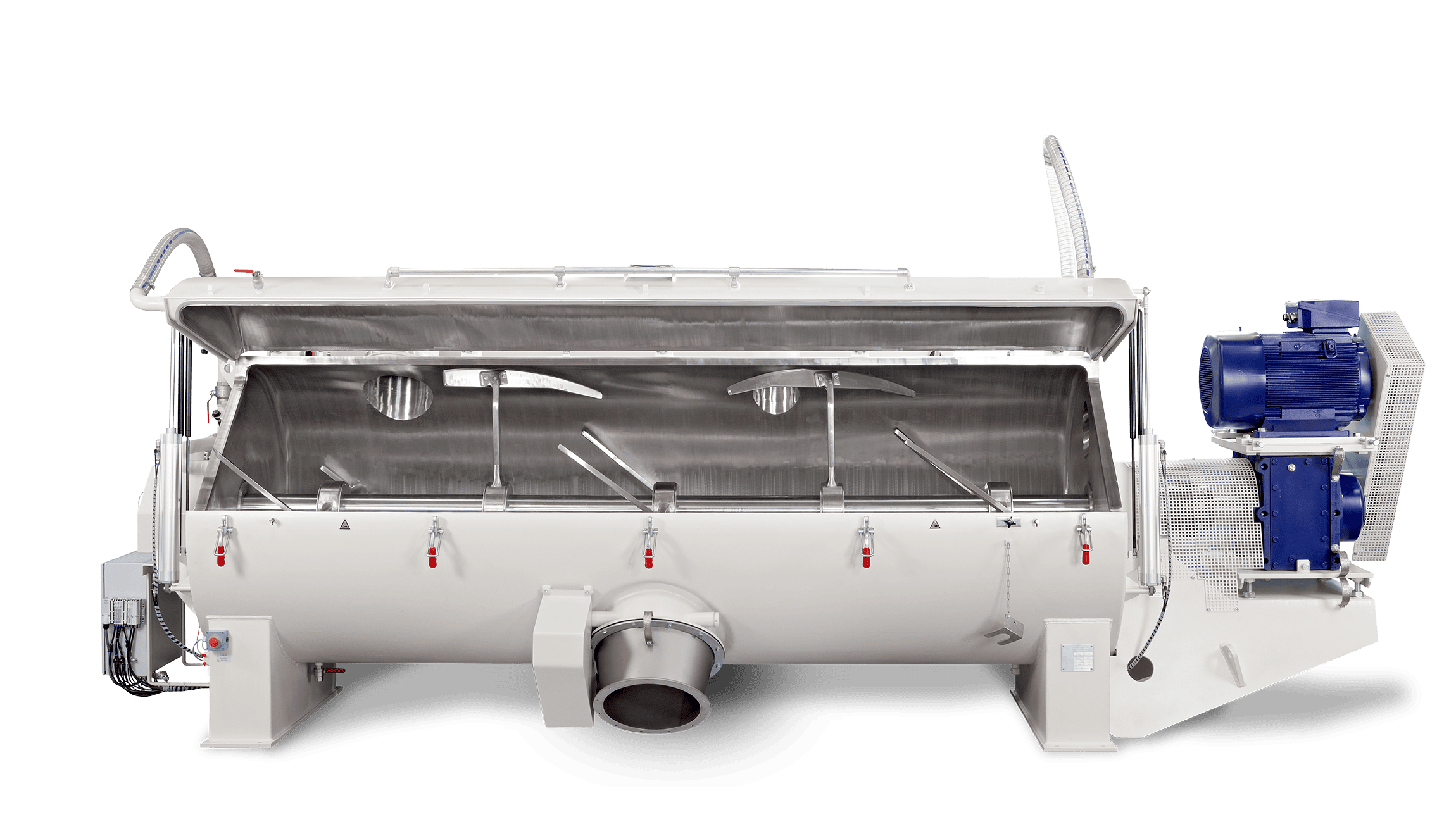

Universal Mixers

Our universal mixers are a versatile solution for demanding process engineering tasks, whether with or without the addition of liquids. Thanks to their outstanding mixing performance, they process raw materials of different particle sizes and bulk densities in the shortest possible time - energy-efficiently and reliably.

Go to Universal Mixers

Heating/Cooling Mixer Combinations

Zeppelin Systems heating/cooling mixer combinations for excellent product quality. Thanks to their intensive mixing action and effective aspiration, they ensure perfect dehumidification of the mix for optimum further processing.

Go to Heating/Cooling Mixer Combinations

CODOS® NT

Our continuous mixing and kneading system CODOS® NT delivers consistent dough quality and top performance – around the clock. The CODOS® NT always achieves consistently optimal results at any time. It excels in gently and intensively mixing both easily and poorly flowing dry materials, as well as liquids and pasty substances in the food sector, always in compliance with specific hygiene regulations.

Go to CODOS NT

Mixing Silos

In the production or recycling of plastics, achieving consistently high product quality can be challenging due to fluctuations in the process or raw materials. Here, gravity mixers make all the difference, as they significantly improve the quality of the end product. Our gravity mixers process large quantities of material with minimal recirculation to achieve a highly homogeneous mixture without additional energy input. This not only saves time and energy but also reduces dust generation. Our mixing silos are recognized by all licensors in the plastics processing industry.

Go to Mixing Silos

DymoMix®

The DymoMix® works extremely fast, dust-free, and produces doughs with a homogeneous consistency. It rapidly moistens flour or other dry ingredients with liquids, applies air, and mixes them before they are introduced into the actual dough-making process. This results in doughs that can be used immediately or fed into batch kneading or continuous kneading systems. The DymoMix® is perfect for use in medium and large industrial operations, especially for pasta, waffle, and pre-doughs.

Go to DymoMixApplication Areas

Industries

Plastics

Technical Plastics

Zeppelin Systems develops customized systems for technical plastics – from conveying to reactor integration. With many years of experience, we support you throughout the entire process: from planning and commissioning to service.

Go to technical plastics

Plastics

Compounding & Plastic Processing

Zeppelin Systems combines innovative technologies with decades of experience and over 10,000 reference plants – ensuring seamless processes from raw material management to packaging.

Go to compounding & plastic processing

Chemistry

Batteries

Zeppelin Systems develops customized, resource-efficient processes for battery slurry production – including a dedicated test environment to ensure optimal results.

Go to batteries

Chemistry

Dispersion Paints

With certified plant technology and comprehensive expertise, Zeppelin Systems offers maximum flexibility and safety across all processes in paint production.

Go to dispersion paintsNeed more details? Our contact person will be happy to assist you

Zeppelin Services

360˚ Service

Zeppelin Systems offers you service with real added value. We deliver not only turnkey plants, but also complete systems, mixers, silos, and components – and support you throughout the execution of your project.

Go to 360˚ services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs—and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutionsResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH