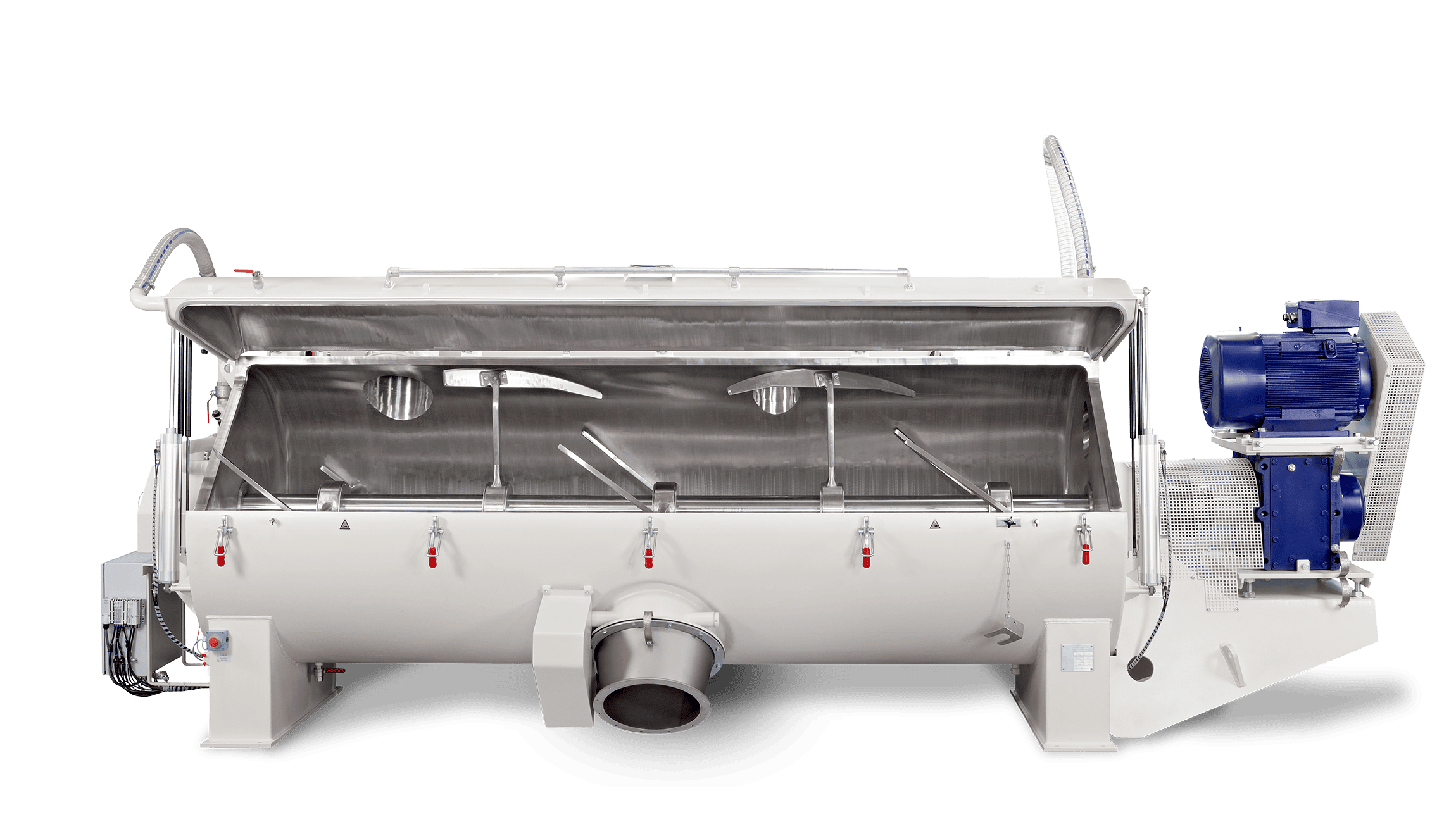

Mixing and Kneading

Mixing, Kneading, Coating, Bonding, Compounding – you name it, we do it!

In product manufacturing, different mixing tasks need to be addressed. Since 1956, Zeppelin Systems has set standards in mixing technology with its HENSCHEL and MTI brand mixers. Whether in the plastics, chemicals, paints and coatings, or food industries, we offer the perfect solution for your mixing task, including process, handling, and processing expertise.

The product portfolio of Zeppelin Systems includes intensive mixers, cooling mixers, as well as heating/cooling mixer combinations, universal mixers, and container mixers – all customized for your specific process. Additionally, we offer various mixing and homogenizing silos, as well as pre-mixers for different doughs and the continuous dough kneading system CODOS NT.

Need more details? Our contact person will be happy to assist you

Explore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH