Sifter

The final touch for a perfect product from Zeppelin Systems

Maximum product quality thanks to efficient classifiers from Zeppelin Systems

You produce top-quality granulates, food products, and recyclates – and the classifiers from Zeppelin Systems provide the finishing touch! Our classifiers clean plastic granulates by removing dust and strands, eliminate films from recycling streams, and extract breakage, dust, and other unwanted particles from food products.

During the processing and conveying of polymer and plastic granulates, unwanted particles may occur, negatively impacting the quality of the end product. Classifiers from Zeppelin Systems clean these granulates quickly and effectively. They also play a key role in recycling applications by separating plastic films from rigid plastics and other contaminants.

Zeppelin Systems classifiers make your products even better!Your advantages at a glance:

- Proven and successful technology

- Wide range of applications: from polymers and technical plastics to soft elastomers, for both recycling and food applications

- Complete program for product cleaning

- For maximum product quality

Versatile classifiers for every application

Drop pipe telescopic classifier FVS

The drop pipe telescopic classifier FVS is suitable as a separator for gravimetric feeding up to 250 t/h. Its key advantage: it can be easily retrofitted, making it an ideal choice as a secondary or downstream classifier.

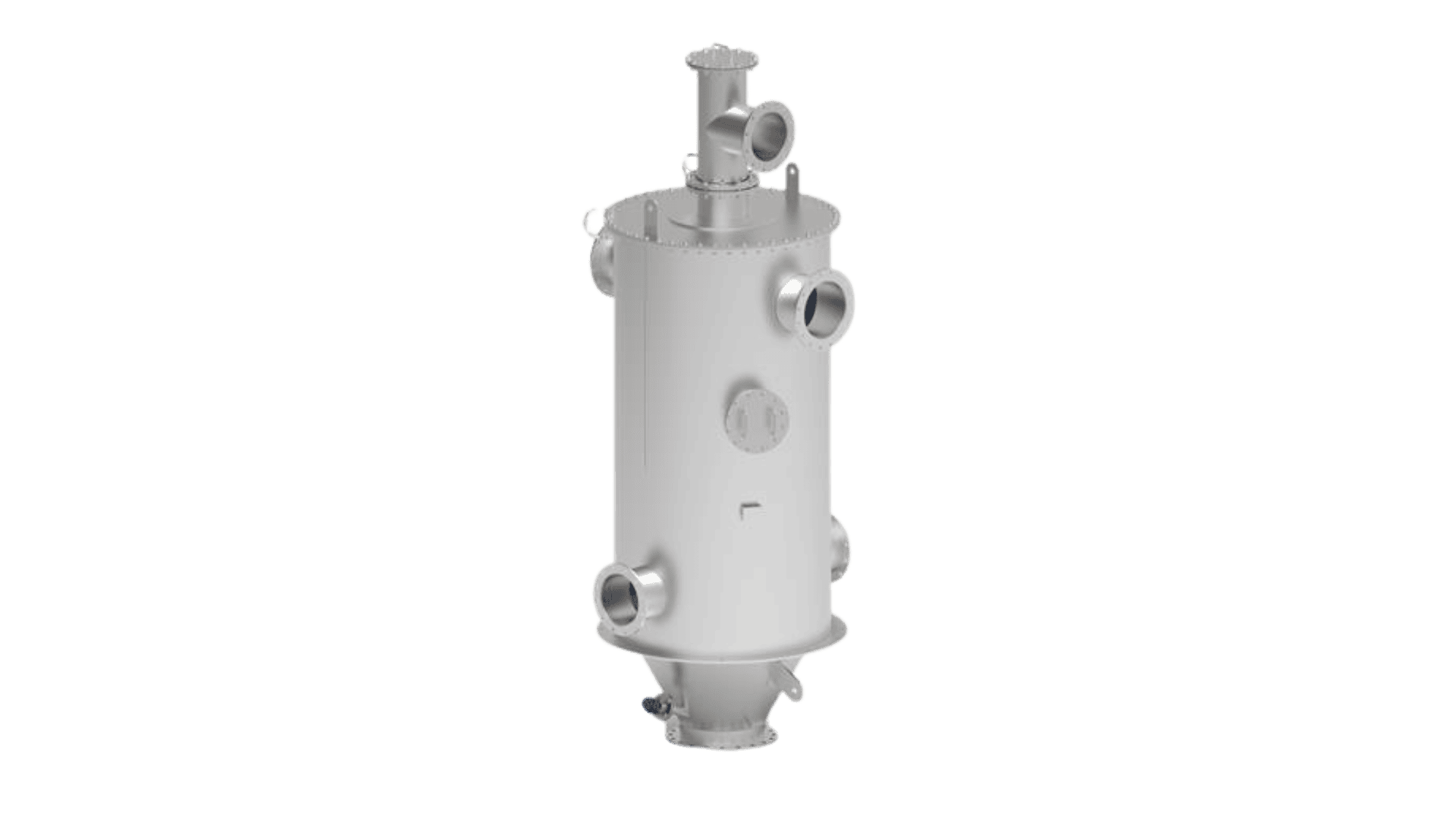

GegCounterflow Classifier GSE

Counterflow classifiers GSE ensure reliable separation of dust particles and fines from plastic granulates while operating in a resource-efficient and energy-saving manner.

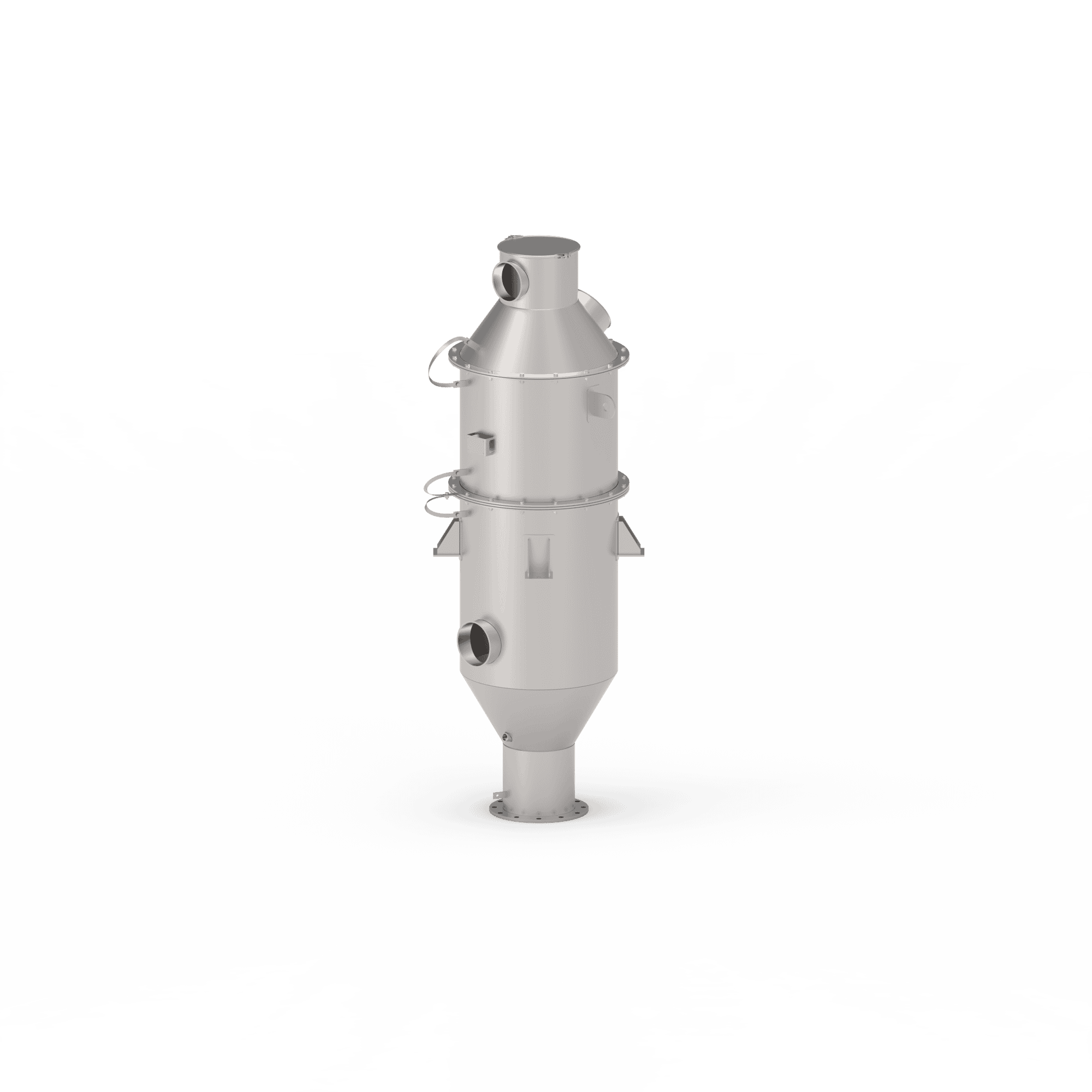

Counterflow Classifier GSF

When used in continuous operation, the counterflow classifier GSF reliably separates lightweight plastic fractions such as films, thin flakes, or layers from heavier fractions like rigid plastics or other contaminants. The GSF classifier is designed so that the product stream is discharged together with the conveying and classification air via the aspiration outlet, while the coarse material is discharged gravimetrically through the lower product outlet.

Counterflow Classifier GTS

The counterflow classifier GTS is characterized by its exceptionally high separation efficiency in removing dust particles and fines from plastic granulates. It is easy to install and maintenance-free.

Benefits

Special Highlights

Effective operation with high separation efficiency

Consistent performance throughout the entire product lifecycle

Maintenance-free thanks to the absence of rotating or wear-prone components

Easy installation and setup

Need more details? Our contact person will be happy to assist you

Further topics you might be interested in

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH