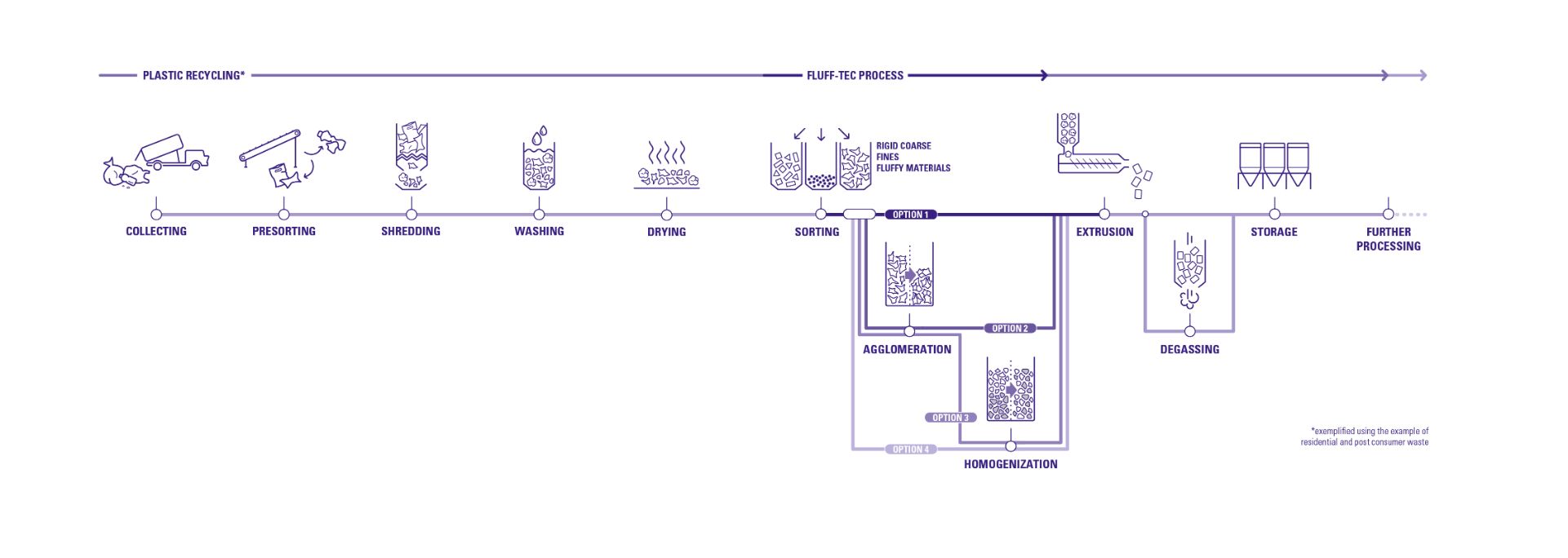

FOR OPTIMAL HANDLING OF FLUFFY MATERIALS

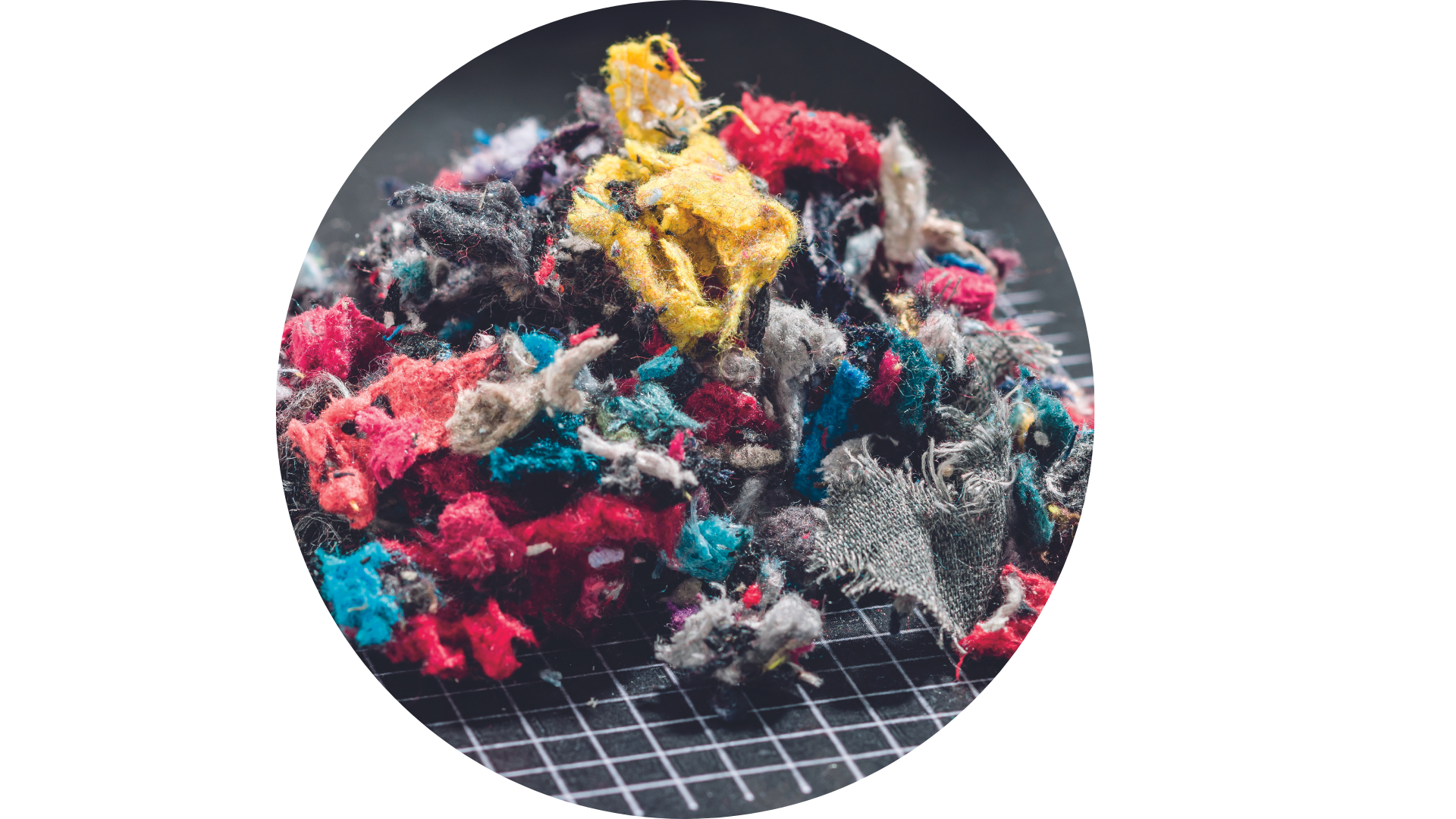

There are already good recycling solutions available for hard coarse material made from PE, PET, PP, ABS or PS. Fluffy materials, on the other hand, are still difficult to deal with. The category of fluffy materials includes soft or thin films, sometimes made of multi-layered packaging materials; hard films, e.g. from hard-shell packaging; but also foams, textile fibers and even wool residues.

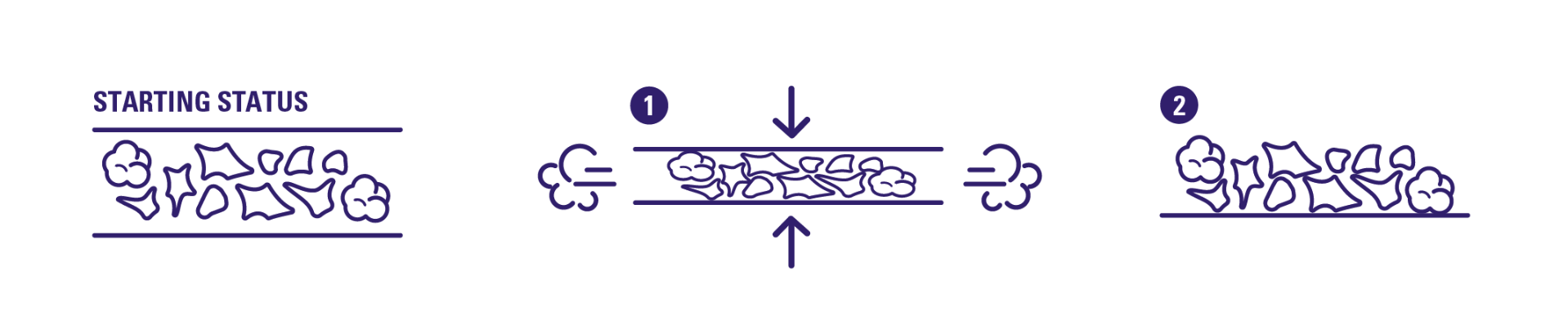

Films are often divided into two categories:

Flexible (2D = type A), such as light agricultural fi lms with very low bulk density and thickness

Rigid (3D = type B), such as PET flakes